X-flow – Leakage Detection Method #SWI2004

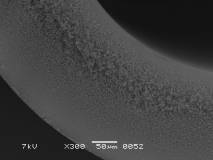

For the purification of water hollow fiber membranes are increasingly being used. These are porous reeds with a diameter of between 1 to 2 mm, made by a particular type of plastic. The ‘wall’ of these reeds has a fine porous structure that is permeable for water, but not for particles of certain sizes. The size of the pores which determines the permeability is in the order of 10 to 500 nanometer (0.01 – 0.5 µm).

A filtration element (a module) comprises several thousand of these reeds glued together and insides a tube. It is of great importance that all reeds in a module are free of defect. Leakage of the reeds can cause troubled product (particles will leak through these imperfections).

Leakage in the reeds can be caused either during the production process or by the handling during the fabrication of the modules. The size of the defects that we want to detect is in the order of 2 – 50 µm. Currently, leakages are detected during the quality control by putting a module underwater and putting air pressure on the outside of the reeds. When there is a leakage in a reeds bubbles will arise from the inside of the reeds The disadvantage of this leakage detection method is that the modules become wet, and they must be dried afterward before shipped to the users. Furthermore, small leakage (<5 µm) can often not be detected because the amount of air slipping through the wall into the reeds is too small to be observed.

We are looking for an improved method, preferably a dry technique (e.g., using acoustical waves), for the detection of leakage in the reeds. To begin with, one can consider a single reed in order to demonstrate the basic ideas. Eventually, a method for the analysis/detection at the module level is preferred. To this end, the application of any existing principle from physics is permitted provided that there are no significant risks to the operators. It should be clear that it must be a non-destructive method.

Input parameters

- Temperature interval of a module: 0 – 50 °C

- Pressure interval:

- From inside to outside: 15 bar

- From outside to inside: 10 bar

- (preference: maximal 3 bar)

- Inner-diameter of the membrane: 800 µm

- Outer-diameter of the membrane: 1300 µm

- Wall Thickness: 250 µm

- Variance in diameters: +/- 50 µm

- The porosity of the wall: 50-80%

- Membrane-pore size: 0.01 – 0.5 µm