Shell – Numerical-physical Modeling of Miscible Fluids in Pipeline Transport #SWI2017

In the oil and gas industry hydrocarbons are transported through long pipelines under various conditions. This transport process generally involves multiple chemical components present in multiple phases (oil, gas, water). The mathematical modeling and simulation of these problems is often done with one-dimensional models that treat the phases as immiscible. However, a particular case that is difficult to model appears when multiple miscible fluids are present in the pipeline. This happens for example when dosing a water-filled pipeline with methanol (to prevent hydrate formation) or when removing gas (such as air or methane) from a pipeline by purging it with inert gas, such as nitrogen. An additional difficulty in predicting this process comes from undulations in the pipeline geometry, which can have a large effect on the mixing process.

Typical questions that we would like to be able to answer are:

- What is the concentration of methanol along the pipeline as a function of time and space?

- How long does it take before the gas originally in place has been removed from the line (i.e. concentration is below a given threshold)?

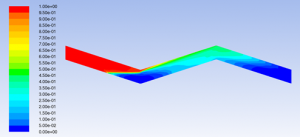

The answer to these questions is often addressed with Computational Fluid Dynamics software (see for example the figure below), based on the solution of partial differential equations. However, this is computationally demanding and offers limited insight into the main parameters that determine the solution. Therefore, in this project, we are interested in simplified analytical or numerical models based on the main physical processes (advection, laminar/turbulent diffusion, gravity currents) that can be used for a quick assessment of pipeline conditions and be used to decide on operating procedures.

Contour plot of methanol mass fraction during injection into a V-shaped line filled with water.